Refine 3D Scans: Mesh Optimization, Repair, and Watertight Checks for Quality Models

Our advanced 3D Scan Refinement service transforms raw scan data into high-quality, usable 3D models. This comprehensive solution addresses common imperfections inherent in initial scans, ensuring your digital assets are precise, structurally sound, and ready for diverse applications. It is designed to prepare complex geometries for visualization, analysis, manufacturing, and archival purposes, providing a solid foundation for any subsequent digital workflow.

Addressing Key Business Challenges

This service meticulously resolves critical issues like mesh irregularities, unwanted noise, holes, and non-manifold geometry often present in raw 3D scans. By delivering optimized and watertight models, it eliminates significant bottlenecks in design, engineering, and quality assurance processes, allowing teams to proceed with confidence and efficiency. It ensures data integrity, crucial for accurate simulations and production.

Effective Application Areas

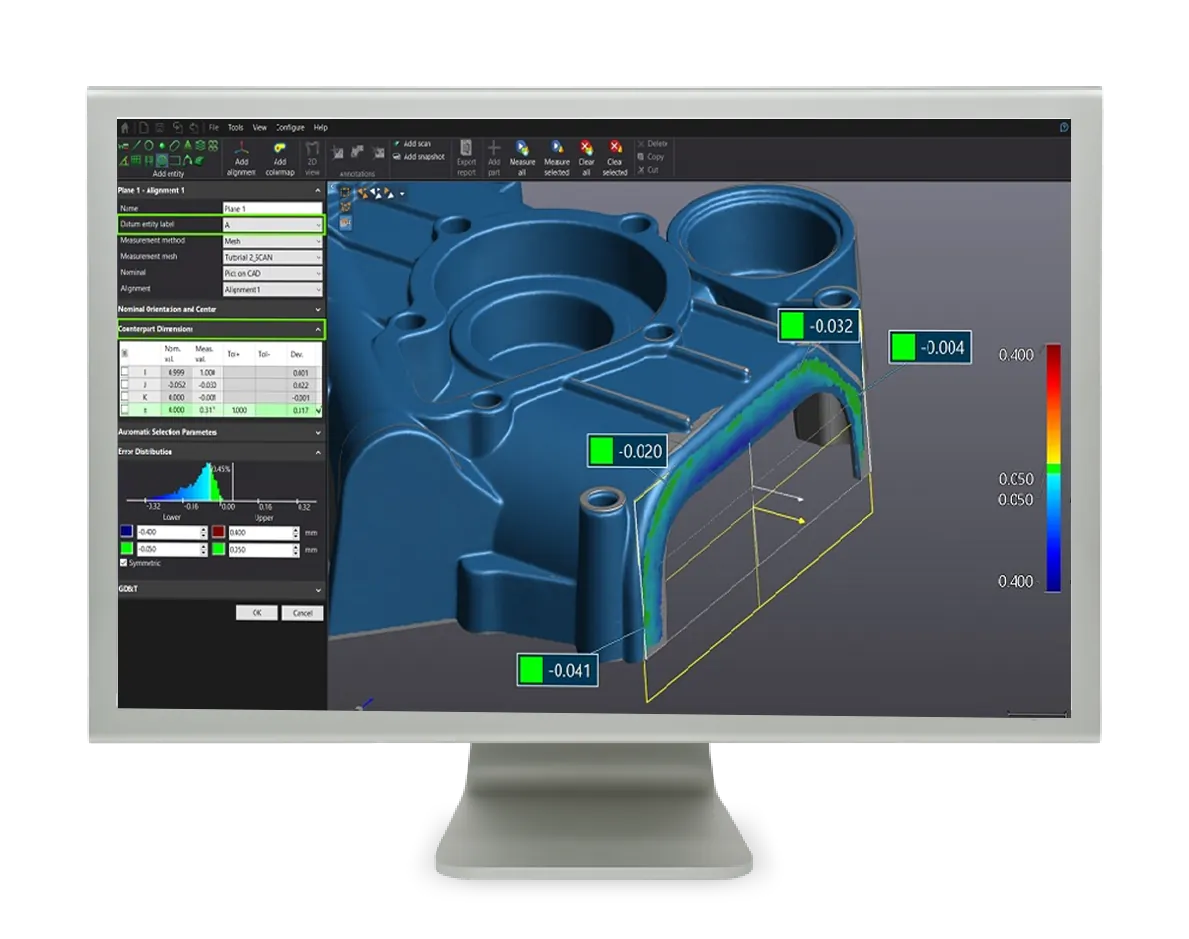

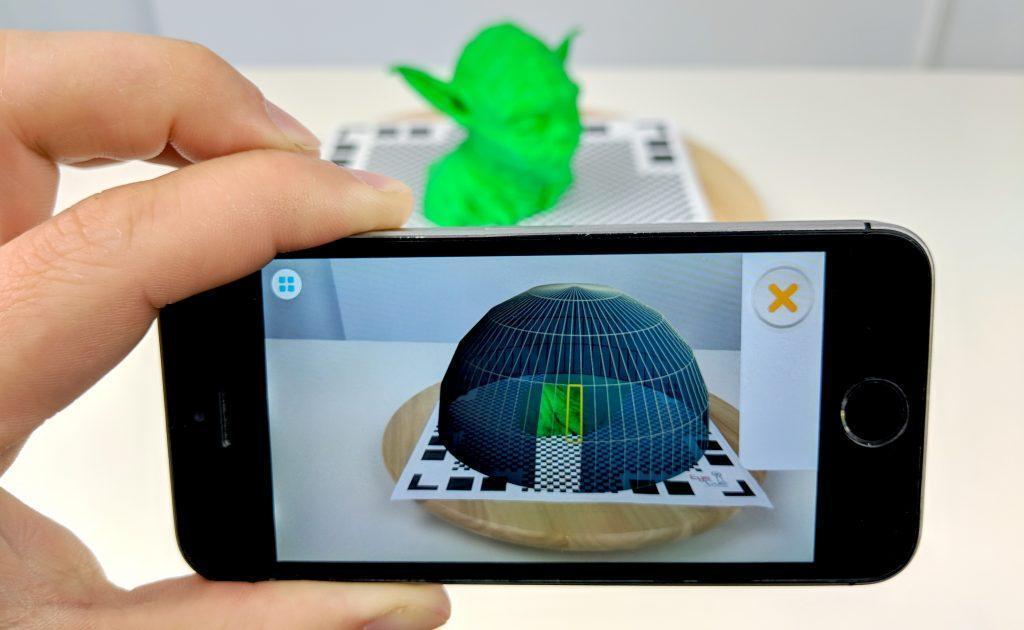

The service proves invaluable across various sectors. In product design and prototyping, it ensures accurate model representation for iterative development. For cultural heritage preservation, it enables the creation of precise digital archives. In manufacturing and quality control, it facilitates reliable inspection and reverse engineering. Furthermore, it significantly enhances models used in augmented and virtual reality experiences, and for robust scientific research.

Key Advantages of Our Service

-

Superior Mesh Optimization: We reduce polygon count while preserving critical details, leading to lighter files that are easier to handle and render without sacrificing visual fidelity.

-

Comprehensive Mesh Repair: Our process automatically identifies and meticulously fixes common scan defects, including holes, gaps, and inverted normals, ensuring geometric integrity.

-

Guaranteed Watertight Models: We ensure all models are fully enclosed and watertight, a fundamental requirement for 3D printing, finite element analysis, and other engineering applications.

-

Enhanced Data Usability: Transforms raw, complex scan data into clean, manageable, and highly functional 3D assets, ready for immediate integration into your workflows.

Service Implementation Process

Our service begins with an initial assessment of your raw 3D scan data. We then proceed with automated and manual mesh repair, addressing any identified imperfections. Optimization techniques are applied to reduce polygon count while maintaining geometric accuracy. Finally, rigorous watertight checks are performed. We leverage industry-leading software and proprietary algorithms, ensuring a streamlined and effective transformation from raw scan to refined model.

Underlying Technologies and Standards

At the core of our refinement process are advanced computational geometry algorithms and robust meshing techniques. We adhere to established industry standards for 3D model data formats and quality metrics. Our methodology incorporates principles of non-destructive editing and iterative refinement, ensuring precision and control. This foundation guarantees models that meet high technical specifications and interoperability.

Anticipated Outcomes and Benefits

Clients can anticipate receiving 3D models that are significantly cleaner, lighter, and geometrically accurate. The output models are consistently watertight, free from internal errors, and optimized for performance across various platforms. This leads to accelerated project timelines, reduced processing overheads, and improved reliability in subsequent digital or physical applications. The refined models provide a superior foundation for all your advanced needs.

Ensuring Quality and Control

Quality assurance is paramount throughout our entire process. Each refined model undergoes multiple layers of validation, including automated error detection and expert manual review. We maintain strict version control and provide detailed reports on all modifications. This meticulous approach ensures the integrity, consistency, and high quality of every model delivered by ScanHub Cloud.

Seamless Integration into Your Workflows

Our refined 3D models are designed for seamless integration into your existing digital pipelines. They are compatible with leading CAD, CAM, CAE, and visualization software. This service acts as a crucial pre-processing step, preparing your data for immediate use in design iterations, simulations, 3D printing, or virtual reality environments, thereby enhancing overall workflow efficiency and data utility.

Conclusion: Driving Business Advancement

The ScanHub Cloud 3D Scan Refinement service is an essential investment for anyone seeking to elevate the quality and usability of their 3D scan data. By transforming imperfect raw scans into optimized, error-free, and watertight models, it empowers businesses to achieve greater accuracy, efficiency, and reliability in their digital endeavors, driving forward innovation and operational excellence.