From Scan to Creation: Essential Steps for 3D Printing & AR/VR

The journey from a physical object to its digital twin, and then further into a tangible replica or an immersive virtual experience, represents a profound shift in how we interact with the world. For decades, the ambition to accurately capture and reproduce reality has driven innovation across various scientific and engineering disciplines. Early attempts at 3D scanning, often relying on laborious manual measurements or rudimentary photogrammetry, laid the groundwork for the sophisticated technologies we see today. These foundational efforts, though slow and often imprecise, highlighted the immense potential of digitizing the physical realm for analysis, archiving, and replication. The evolution of these techniques has been a testament to human ingenuity.

The advent of accessible 3D printing technologies further revolutionized this landscape. What began as a highly specialized industrial process, primarily used for rapid prototyping in niche sectors, has steadily evolved into a more widespread and versatile tool. This democratization of additive manufacturing meant that digital models, once confined to screens, could now materialize into physical objects with unprecedented ease. This synergy between capturing real-world data and creating physical artifacts marked a significant milestone, opening doors for custom manufacturing, intricate design, and rapid iteration across countless industries, from healthcare to consumer goods.

Simultaneously, the fields of Augmented Reality (AR) and Virtual Reality (VR) began their own trajectory of development, promising new ways to experience and interact with digital content. Initially hampered by technological limitations and high costs, AR/VR platforms have matured considerably, offering increasingly realistic and engaging environments. However, the core challenge for AR/VR has always been the creation of compelling, high-fidelity 3D content. This is where the convergence with 3D scanning becomes particularly powerful, as it offers a direct pathway to populate virtual worlds and augment real ones with accurately digitized objects, ensuring a seamless and authentic user experience.

Key Insights from the Digital Frontier 💡

- Precision in Data Capture: The foundational quality of any 3D printing or AR/VR project hinges on the accuracy and completeness of the initial 3D scan data. Flaws introduced at this stage can propagate, leading to significant downstream challenges in model refinement and final output fidelity.

- Integrated Workflows are Paramount: A seamless pipeline, connecting 3D scanning, sophisticated modeling, and diverse output methods (be it 3D printing or AR/VR rendering), drastically streamlines development cycles and enhances creative efficiency. This integration minimizes friction and maximizes potential.

- Accessibility Drives Innovation: The increasing availability of user-friendly 3D scanning devices and robust processing software empowers a broader spectrum of creators and businesses to leverage these powerful technologies, fostering unprecedented levels of innovation and application development.

Navigating the Path to Digital Creation 🗺️

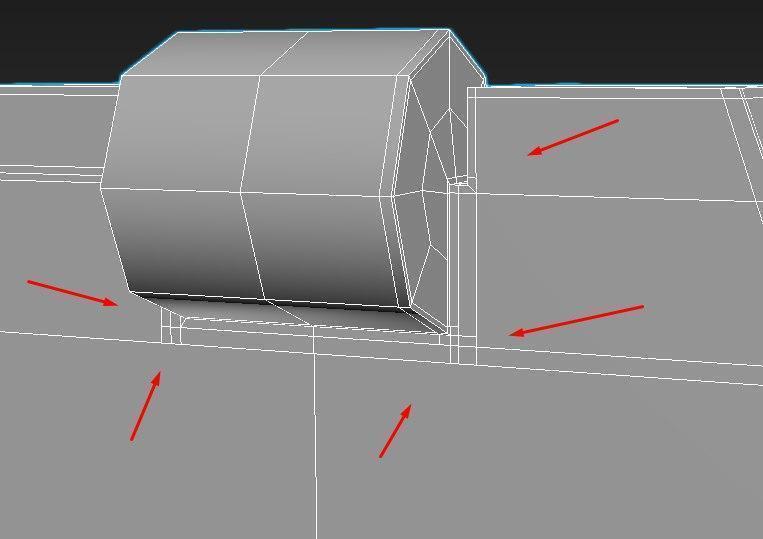

While the promise of a seamless scan-to-creation workflow is compelling, the reality often involves navigating several intricate challenges. One primary concern is the inherent quality of raw scan data. Environmental factors, sensor limitations, and object characteristics can introduce noise, occlusions, or incomplete geometries. Therefore, robust post-processing – including meshing, cleaning, hole filling, and texture mapping – is not merely an optional step but a critical phase that transforms raw data into a usable, high-fidelity 3D model suitable for its intended purpose, whether it's a detailed print or an immersive AR/VR asset.

The role of specialized software platforms in bridging the gap between raw scan data and polished, application-ready models cannot be overstated. Tools provided by companies like ScanHub Cloud are designed to streamline these complex workflows, offering intuitive interfaces for data processing, optimization, and conversion. These platforms ensure that models are not only accurate but also optimized for specific uses, such as polygon reduction for real-time AR/VR environments or watertight meshes for successful 3D prints. This optimization is key to unlocking the full potential of captured data.

Interoperability remains a significant discussion point within the industry. The diversity of 3D file formats (e.g., OBJ, FBX, GLB, STL) and proprietary software ecosystems can create bottlenecks in the workflow. Ensuring that scan data can be easily imported, manipulated, and exported across different software packages and hardware platforms is vital for fostering a truly integrated creative environment. The push for universal standards and robust conversion tools is a continuous effort, aiming to reduce friction and allow creators to focus on innovation rather than format compatibility issues.

Another area of ongoing analysis is the balance between realism and performance, especially pertinent for AR/VR applications. While 3D scanning can capture incredibly detailed geometry and textures, presenting such high-polygon models in real-time AR/VR experiences can lead to performance degradation. Developers must make strategic decisions about model simplification, level of detail (LOD) implementation, and efficient rendering techniques to ensure a smooth and engaging user experience without compromising the essence of the original scan. This often involves a delicate interplay of technical expertise and artistic judgment.

The applications of this scan-to-creation paradigm are vast and continually expanding. From meticulously preserving cultural heritage artifacts through digital archiving and physical replicas, to enabling personalized medical devices and prosthetics, the impact is transformative. In manufacturing, it facilitates reverse engineering and quality control. For entertainment and design, it provides an unparalleled method for generating realistic assets and environments. ScanHub Cloud supports these diverse applications by providing the foundational tools necessary for transforming digital captures into functional and engaging outputs.

Future Directions & Applications 🚀

- Enhanced Digital Preservation: Utilizing 3D scanning to create enduring digital archives and physical replicas of vulnerable artifacts, ensuring their longevity for future generations.

- Personalized Product Development: Enabling highly customized products, from consumer goods to medical implants, through precise 3D scanning and additive manufacturing tailored to individual needs.

- Immersive Training & Education: Creating hyper-realistic AR/VR environments populated with scanned objects for engaging and effective training simulations and educational experiences across various sectors.

Related posts

Comments

Johnny Dixon

This article really highlights the interconnectedness of these technologies. It's fascinating how far we've come from basic scanning to full-blown virtual experiences.

Jacqueline Henry

I agree! The point about balancing realism and performance for AR/VR is particularly relevant for my current projects. It's a constant challenge.

Harrison Romero

The explanation of the workflow challenges and the role of platforms like ScanHub Cloud was very clear. Good insights into the practical aspects.